The IHS offers a wide range of services in the field of flow measurement. Here we inform you among other things about the equipment of our laboratory.

The IHS offers a wide range of services in the field of flow measurement. Here we inform you among other things about the equipment of our laboratory.

Contact information:

Please direct requests to Dr.-Ing. O. Kirschner.

Laboratory

In the laboratory of the institute different permanently installed test rigs are available for various experimental investigations. In all test rigs, the flow characteristics of valves, pumps and turbines are measured. Thanks to a large number of measuring instruments with a wide variety of measuring principles and the selection of test rigs, very different measuring application are possible in the laboratory.

An excerpt of activities carried out:

- Creation of hill charts

- Velocity measurement with LDA and PIV

- Experimental investigation of cavitation

- Experimental investigation of the transient operation of hydraulic machinery

- Acoustic emission measurements

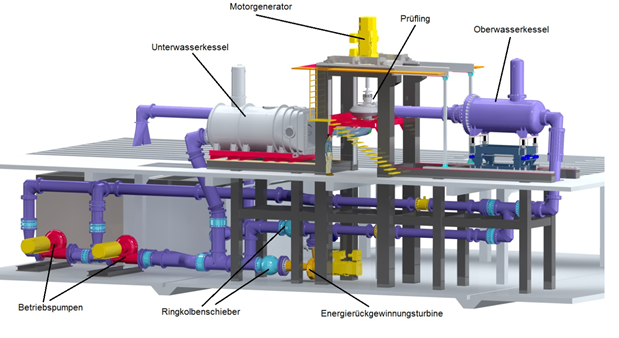

Test Rig for Operational Transients of Hydraulic Machinery

The new test rig enables the investigation of operational transients in hydraulic machinery. Since both the operating pumps and the turbomachine under investigation (test specimen), as well as the energy recovery turbine and the annular piston valves, can be precisely regulated or controlled during operation, this setup allows for the replication of defined transient operating conditions of the prototype system on the test specimen. This includes start-up and shut-down processes, as well as transitions between pump and turbine operation, and in particular the reverse. All turbomachines are operated at variable speeds, enabling all four operating quadrants to be set on the test specimen.

Acknowledgment

We thank the German Research Foundation (DFG), the Ministry of Science, Research, and the Arts of Baden-Württemberg, and the University of Stuttgart for their financial support of this large-scale research device.

Table 1: Operational Data of the Dynamic Circuit

| Max. discharge | Max. pressure | |

|---|---|---|

| Pumps in serial operation | Qmax = 0,6 m³/s | pmax = 12 bar |

| Pumps in parallel operation | Qmax = 1,2 m³/s | pmax = 6 bar |

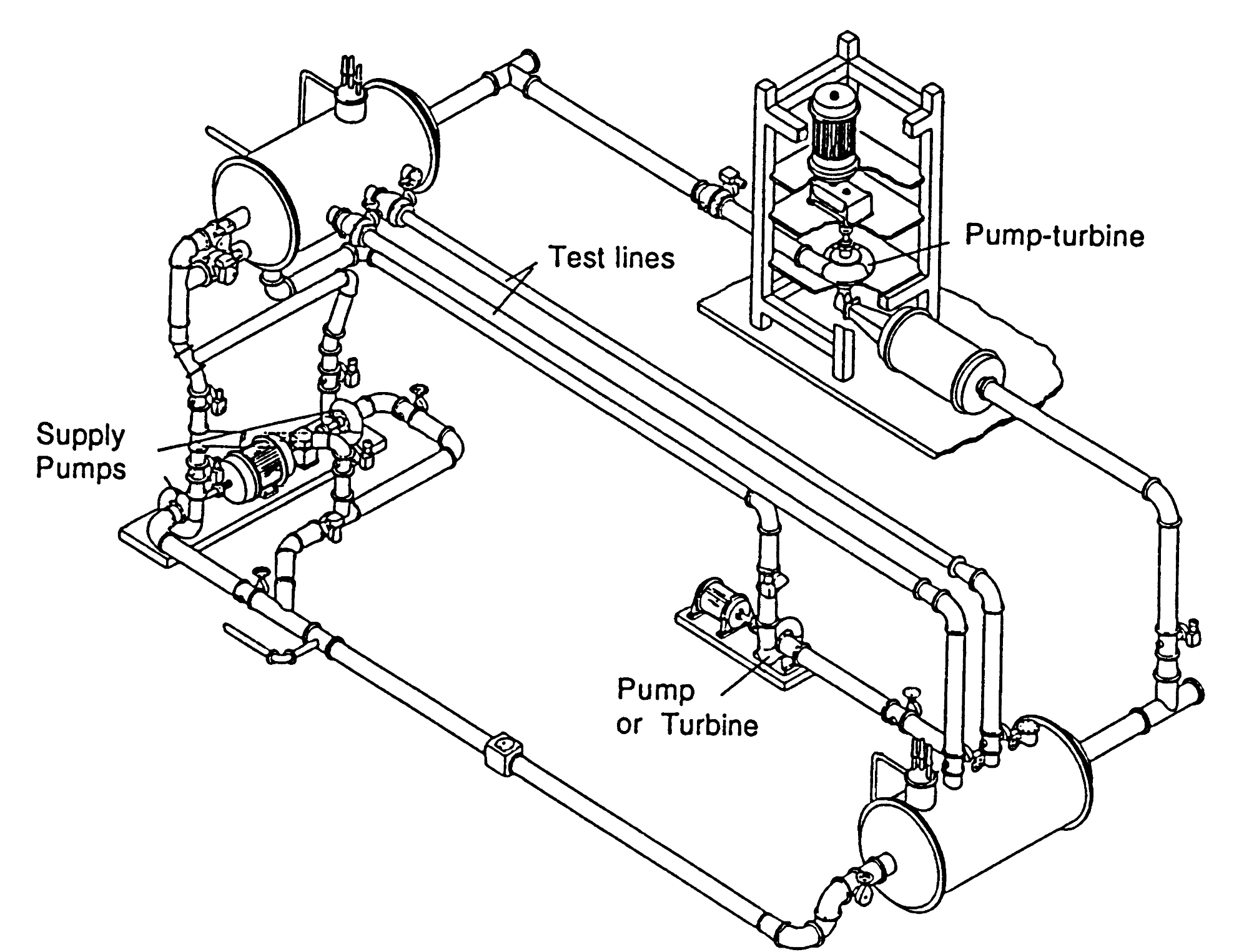

Closed loop test rig

A closed loop test rig allows examinations at different pressure levels. The tail-water-vessel is equipped with an air-chamber; this air- chamber can be used to adjust the pressure level in the test rig. In addition, a vacuum pump is connected to the tail-water-vessel in order to lower the pressure level for cavitation tests below the ambient pressure.

A closed loop test rig allows examinations at different pressure levels. The tail-water-vessel is equipped with an air-chamber; this air- chamber can be used to adjust the pressure level in the test rig. In addition, a vacuum pump is connected to the tail-water-vessel in order to lower the pressure level for cavitation tests below the ambient pressure.

Table 2: Operating data of the closed loop test rig.

| Max. discharge | Max. pressure | |

|---|---|---|

| Pumps in serial operation | Qmax = 0,25 m³/s | pmax = 10 bar |

| Pumps in parallel operation | Qmax = 0,5 m³/s | pmax = 5 bar |

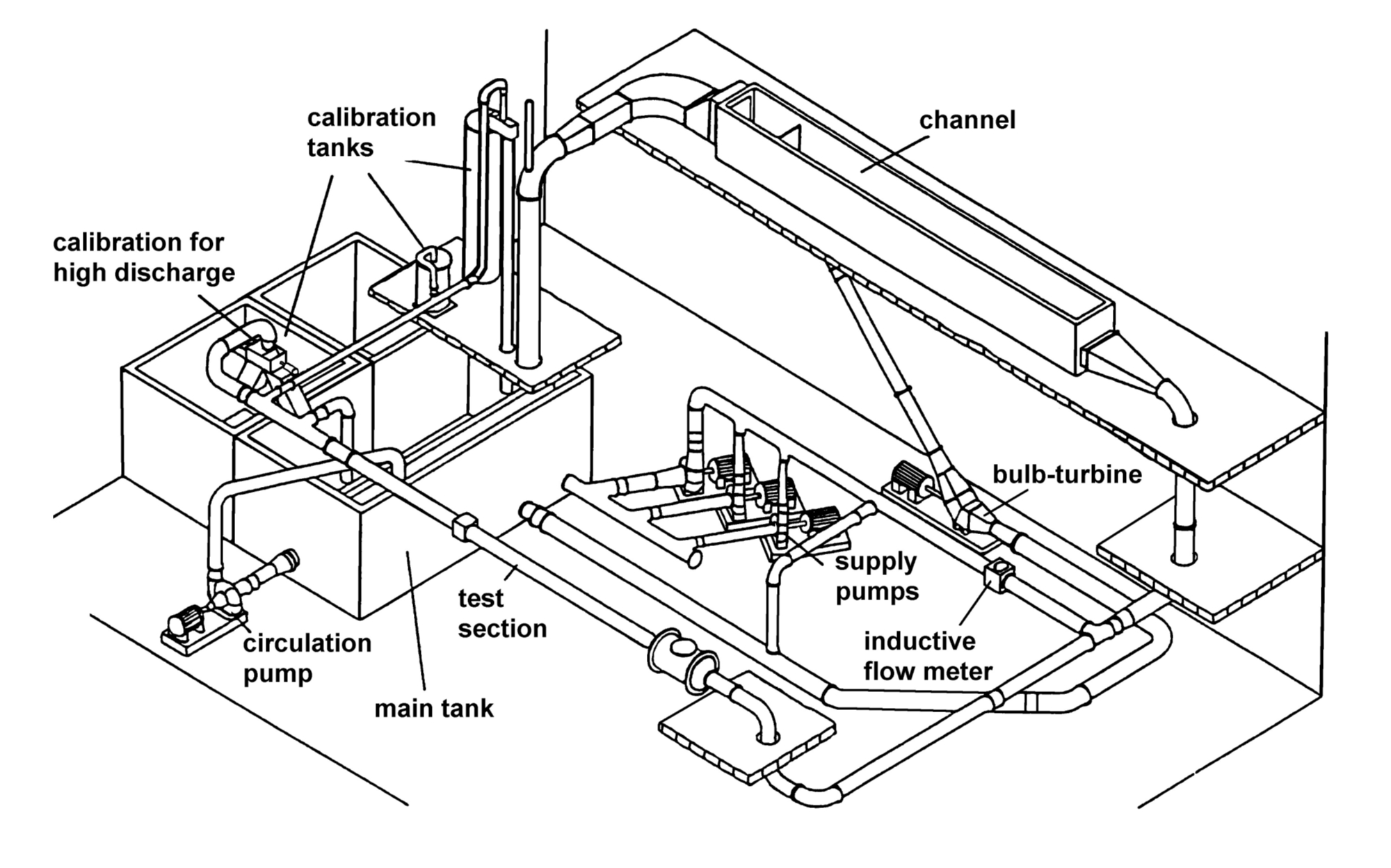

Open loop test rig

Depending on the application, a small open low pressure test rig, a large open low pressure test rig with three pumps and an open high pressure test rig are available. The open high-pressure test rig leads through an anechoic room. Here acoustic measurements can be made on valves, smaller pump units or other models. In the large open low pressure test rig, the water can be pumped through the test section with a bulb-turbine or into a flume.

Depending on the application, a small open low pressure test rig, a large open low pressure test rig with three pumps and an open high pressure test rig are available. The open high-pressure test rig leads through an anechoic room. Here acoustic measurements can be made on valves, smaller pump units or other models. In the large open low pressure test rig, the water can be pumped through the test section with a bulb-turbine or into a flume.

Table 3: Operating data of the pumps of open loop test rigs

| Discharge | Pressure | |

|---|---|---|

| Small low pressure open loop test rig | Q = 0,025 m³/s | p = 7 bar |

| Big low pressure open loop test rig | Q1 = 0,83 m³/s Q2 = 0,28 m³/s Q3 = 0,17 m³/s |

p1 = 0,7 bar p2 = 4 bar p3 = 8 bar |

| High pressure open loop test rig | Q= 0,02 m³/s | p = 55 bar |

Workshop

A workshop is available at the institute for the construction and production of test stands and test rigs. It is equipped with conventional cutting machines, welders and various power tools. The workshop employees have many years of experience in handling turbomachinery and measuring technology.

A workshop is available at the institute for the construction and production of test stands and test rigs. It is equipped with conventional cutting machines, welders and various power tools. The workshop employees have many years of experience in handling turbomachinery and measuring technology.

Other equipment

In addition to the water test rigs, a small wind tunnel is also available for experiments. In addition to the fixed test rigs described above, several smaller pumps and pipes are still available in the laboratory to allow flexible short-term test rigs with lower flow rates.

Measurements on site

With the large number of measuring devices with different measuring principles, flexible measuring campaigns can also be implemented in difficult locations. Examples of measurements already taken:

- Efficiency measurements on hydroelectric power plants

- Checking the control quality of hydropower plants

- Efficiency measurements on pumps

- Sound measurement and acoustic spectral analysis